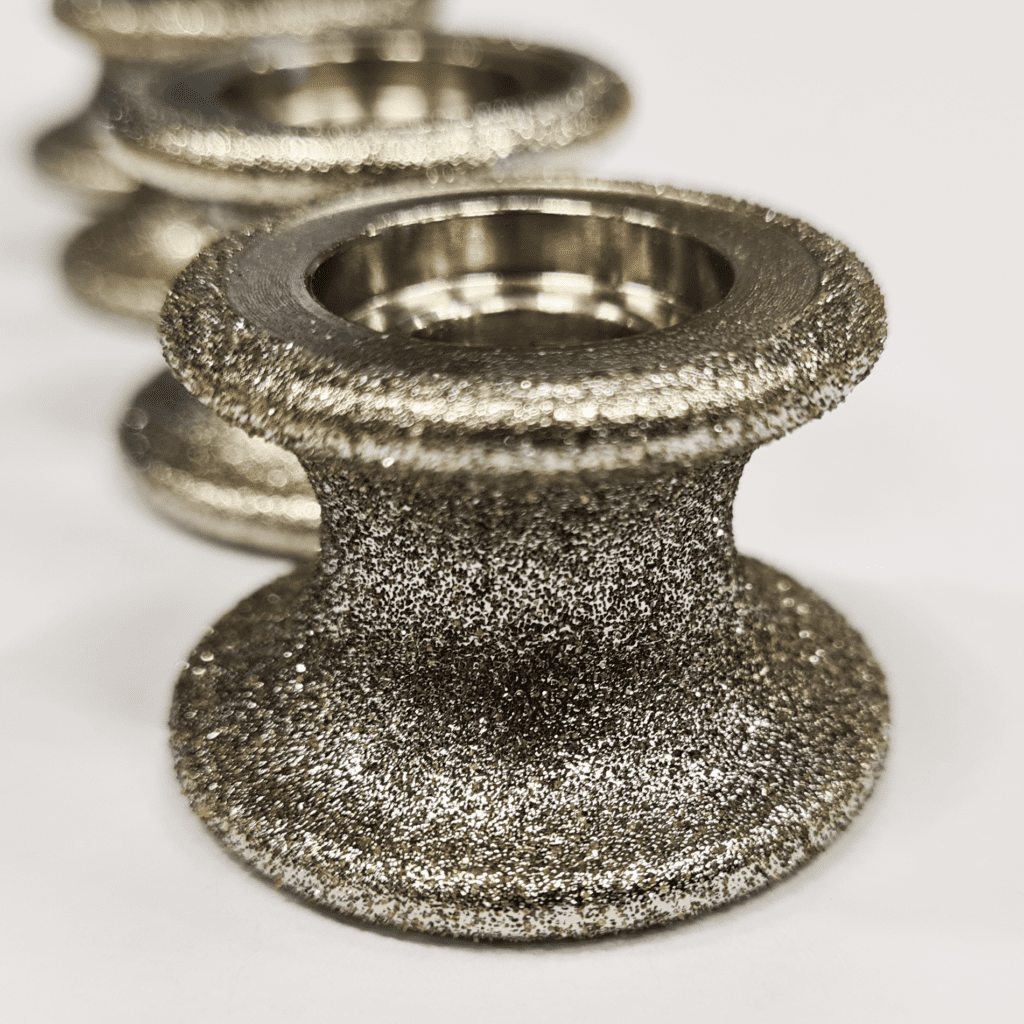

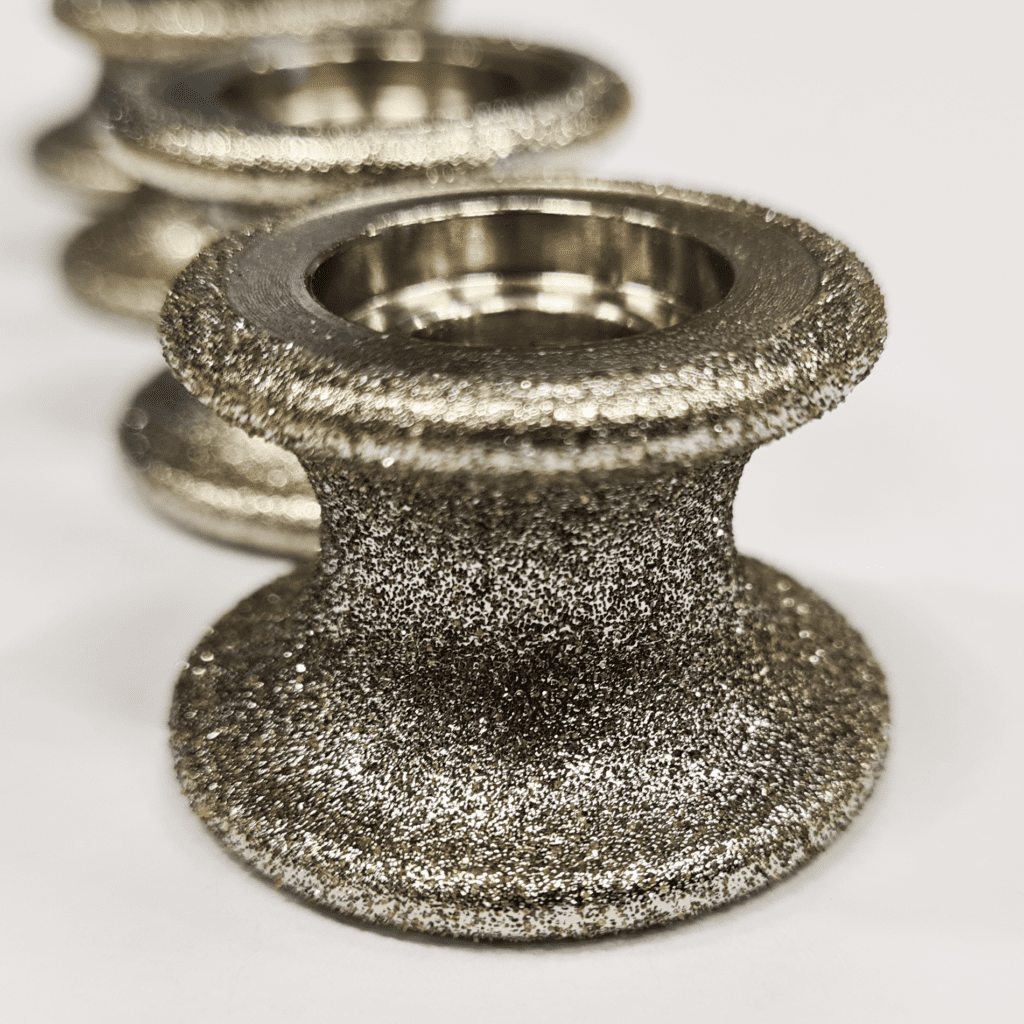

Grinding wheels:

Diamond wheels for regrinding carbide buttons

Restore your grinding performance. On the rig or in the grinding shop.

- Our grinding wheels are available in spherical, ballistic and trubbnos configurations.

- The diameters range from 7 to 19 mm.

- The wheels are performance testet in our in house grinding test facility

- Our wheels come in environmentally conscious packaging made from paper and bio-plastics

- All our products are made in Europe

Superior reshaping

Using diamond wheels is the most precise method to restore the original shape of carbide buttons. The grinding wheels keep restoring the shape of the buttons during its entire lifetime compared to for example grinding cups that tend to flatten or sharpen during its lifetime. If your drilling operation has high demands for a specific shape, the grinding wheel should be your top choice for regrinding. Restoring the shape means restoring performance.

Performance you can trust

Our wheels are consistently performance tested to maintain grinding performance, lifetime and sharpness.

Download PDF with full GMTT grinding wheels list.

Products

Spherical Grinding wheels

The spherical grinding wheel is a commonly used profile for reshaping carbide buttons.

Standard diamond grain wheel.

Button type:

Spherical size 7–20 mm

Ballistic Grinding wheels

The ballistic wheel has a steeper profile and still maintains a consistent regrinding result with a precise restoration of the carbide button shape.

Standard diamond grain wheel.

Button type:

Spherical size 7–20 mm

Ballistic size 7–19 mm

Full ballistic 9